Types of Locking Mechanisms for Knives

If you've ever shopped for an everyday carry pocket knife, you know that you have a bewildering array of options to choose from. Trying to understand the many types of knives and their subtle differences can be overwhelming. Among the many factors to consider when choosing something as personal as a knife, its locking mechanism is one of the most important. Before investing in a quality knife, you should know what type of lock, if any, is best suited to your needs and preferences.

In this article, we'll introduce you to some of the most common types of locking mechanisms you'll find in your desired EDC (everyday carry) knife. You'll discover the benefits of knives that lock, which type is best suited for your EDC, and how they function.

Friction (Slip Joint Mechanism)

Friction knives are practical, simple, and intuitive.

Calling a knife a friction folder doesn't tell the whole story. Friction folding knives don't actually lock at all. When closed, the blade has a long tang extending from it. Flip the blade open, and that's it! In a sense, it's a locking system, as your hand prevents the blade from closing during use.

One of the main advantages of these knives is their legality. They're also easy to carry since they're straightforward and user-friendly. However, it's worth noting that these knives lack a true lock, making them less suitable for more demanding tasks.

Pros: Legal, simplicity of use

Cons: Unsuitable for heavy-duty tasks, higher risk of accidentally closing on fingers, not suitable for stabbing, care needed for proper cutting direction

Ring Lock - Virobloc (Primarily by Opinel)

Ring lock knives are simple, unique, and intuitive. Not many companies manufacture ring lock knives. Opinel is the most popular brand known for its ring lock knives (though Cold Steel also had its version in the past). A rotating collar around the handle of the blade freely turns, allowing for locking in the open or closed position. This system excels in its simplicity and ease of use but can be more complex when disassembling. Opinel refers to it as the Virobloc lock.

Pros: Ease of use, even for non-knife users; legality in many countries; good safety with the locking ring

Cons: Requires two-handed manipulation to open and close

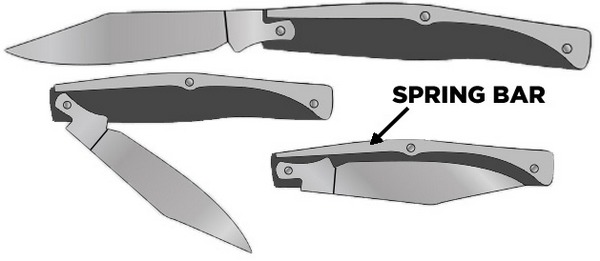

Slipjoint

Slipjoint knives are classic, reliable, and traditional.

Slipjoint knives lack a lock. They use a tensioned back spring to keep the blade open or closed. Exercise caution when cutting with a slipjoint. Any pressure on the spine of the blade could potentially close it directly on your fingers. However, slipjoints are much safer to use than friction folders.

Pros: Legal in most countries, simplicity

Cons: Not a complete locking mechanism, not suitable for stabbing, requires two-handed operation

Backlock (Lockback)

Backlock knives are sturdy, classic, and simple.

Lockbacks, also known as backlocks, were popularized by Buck Knives in the 20th century. The back lock relies on a notch in the blade tang and a rotating latch. The latch prevents excessive movement or play of the blade in the open position. Depressing the back latch releases the blade for closing.

Among the advantages of a lockback are reliability, safety, and ambidextrous operation. The unlocking button doesn't obstruct your hand while using the knife, minimizing the risk of accidentally releasing the lock. When closing, your hand is also kept away from the blade path, reducing the risk of cuts.

One drawback is that while it's possible to close the lock one-handed, it's not as straightforward. Closing the blade might require more attention to prevent accidental release.

Pros: Ambidextrous use, simplicity, safety, and strength, easy use with gloves

Cons: Potentially more complex reassembly after disassembly, care needed for one-handed closing

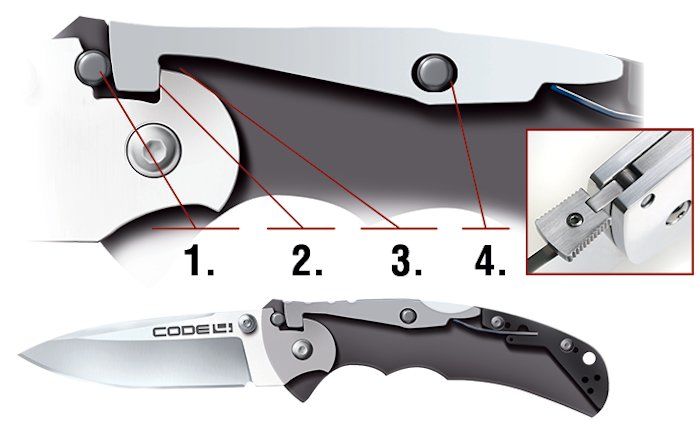

Tri-Ad Lock (Exclusive to Cold Steel)

Cold Steel is perhaps best known for its Tri-Ad® lock, which has proven to be one of the most secure locking systems on the market in rigorous torture tests. Designed by renowned knife designer and Cold Steel collaborator Andrew Demko, the Tri-Ad® lock uses a combination of features that respond exceptionally well to both positive and negative pressure, withstanding loads of up to 800 pounds of hanging weights.

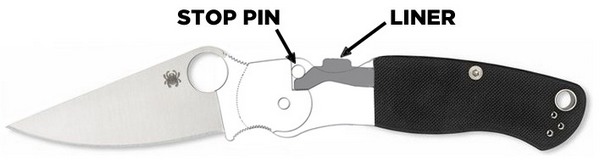

The blade rests against a stop pin for increased wear resistance. The stop pin cushions and redistributes the force on the blade. Additional space is provided for the stop pin to drop deeper into the detent over time, reacting to normal wear. The entire surface of the lock and blade tang interface are flush. The slightly inclined lock tends to push the lock inward under pressure rather than outward. The lock's detent hole has extra space on both sides for personal adjustment through use and time.

Pros: Extremely strong and reliable, suitable for heavy-duty tasks, self-adjustment over time, ambidextrous mechanism, easy use with gloves

Cons: Spring force can be very strong, stronger thumb recommended, attention needed for one-handed closing

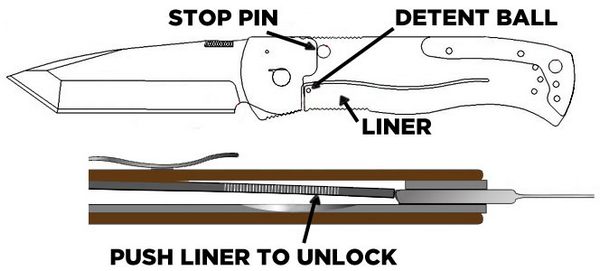

Linerlock

Linerlock knives are simple and widely available.

In the modern knife community, the most prevalent locking mechanism is the liner lock. When the blade rotates into the open position, a tensioned piece of metal slides into place and engages the blade's tang. This tension keeps the knife locked open with a small chance or risk of accidentally closing on your hand during use.

If you plan to use your knife for demanding tasks, it's worth noting that liner locks are generally not as robust as other locking systems. While still sufficiently strong, they are usually made from thinner pieces of metal, making them more susceptible to wear compared to, for example, a massive frame lock.

Pros: Simplicity, availability, easy maintenance and folding

Cons: Theoretically more complicated for left-handed users, great for general use, not as suitable for heavy-duty tasks

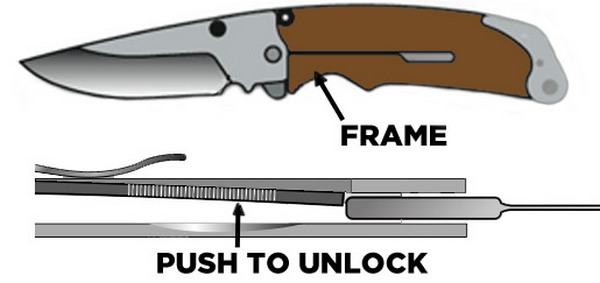

Framelock

Framelock knives are strong, reliable, and common. The frame lock is very similar to the liner lock. The main difference is that, instead of a metal insert serving as the lock, the actual handle frame of the knife functions as the lock. Frame locks are often found on knives with titanium handles, as titanium is highly resistant to torsional forces. This locking mechanism (sometimes referred to as the Reeve Integral Lock) was invented and popularized by Chris Reeve.

This type of locking system places a significant amount of metal against the blade, ensuring a strong lock for piercing, cutting, slicing, and other demanding tasks. Frame locks are visible on many mid-range to high-end knives, usually made from titanium. A metal insert is often installed on the contact surface to enhance durability. It's interesting to note that the safety feature is increased by simply gripping the knife handle, which pushes the lock inward.

Pros: Strength, availability, straightforward assembly and disassembly

Cons: Often used in higher-end knives, not fully ambidextrous, care needed to prevent fingers from being on the blade when opening, potentially challenging to open

Compression Lock (Exclusive to Spyderco)

Compression knives are strong, unique, and fun.

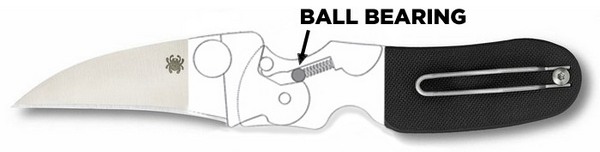

The Compression Lock is a mechanism developed and patented by Spyderco. In their own words, the Compression Lock is a locking mechanism using a leaf spring from a split liner in the handle to wedge a ball bearing between a ramp on the blade tang and a stop pin (or a blade's detent ball). While it might sound complex, functionally, this system excels in its easy one-handed operation.

While its strength is significantly enhanced with the Compression Lock, its straightforward use still allows for secure and easy one-handed opening and closing, similar to a liner lock.

It's often mislabeled and compared as a reverse liner lock, which is not entirely accurate. The Compression Lock is much stronger and easier to use.

Pros: High reliability and strength, very smooth operation, high safety during closing as fingers are out of the blade's path, perfect one-handed operation (for right-handers)

Cons: Not entirely optimal for left-handed users

Axis Lock, Clutch Lock, Crossbar Lock, etc.

Axis Lock knives are ambidextrous, strong, and fun.

This locking mechanism was originally designed and patented in 1988 by knife makers Bill McHenry and Jason Williams, who later sold the mechanism's rights to Benchmade. Benchmade renamed it the AXIS Lock and has since used it in dozens of iconic knife models to this day. Although the patent itself expired in 2018, leading to the development of similar mechanisms by other knife manufacturers, the AXIS lock brand and trademark remain with Benchmade and continue to be used in their designs.

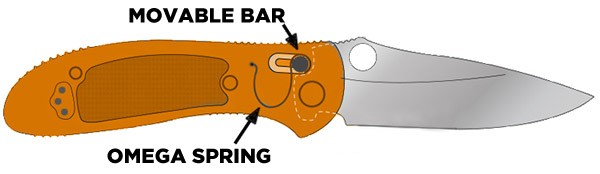

The fully ambidextrous AXIS Lock is among the most intuitive systems in operation, though describing the mechanism isn't quite as simple. Omega springs tension the AXIS bar against notches in the blade. Pull back the AXIS bar to create enough play for the blade to rotate open or closed. The Omega springs provide locking tension between the stop pin and the AXIS bar. The AXIS lock usually operates very smoothly, with the blade dropping freely after being released.

Pros: Truly ambidextrous lock, intuitive operation and smooth action, high strength

Cons: Possibility of breaking the 'Omega' spring, potentially complicated knife assembly during maintenance, numerous parts

Ball Bearing Lock (Exclusive to Spyderco)

The patented Compression Lock employs a ball bearing wedged between a solid stop pin and the blade's tang. The mechanism also serves as a stop to keep the blade closed. It functions similarly to the Axis Lock but employs a traditional spiral spring instead of Omega springs.

This is a very strong locking mechanism that operates simply and intuitively. It's usable even when wearing gloves, a significant advantage, and fingers are out of the blade's path when closing.

The ball bearing is loosely anchored and rotates during use, making it nearly impossible to wear out.

Pros: Truly ambidextrous lock, intuitive operation and smooth action, high strength, usable with gloves

Cons: Limited availability of models with this mechanism

Button Lock

Button lock knives are reliable, durable, and often found in automatics.

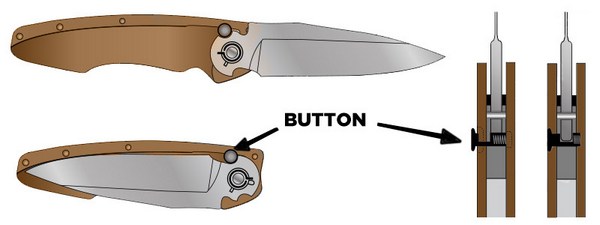

Pressing the button releases the locking and transfers spring tension. An internal piston system is responsible for locking in both the open and closed positions. On manually operated button lock knives, an opening mechanism is required, such as a flipper or thumb stud.

Pros: Very easy operation, all action initiated by pressing the button, very smooth operation and safe use with manually operated knives, fingers are out of the blade's path during closing

Cons: With some designs, care must be taken to avoid accidentally pressing the button and releasing the blade during use

Fixed Blade

For maximum strength, you need a fixed blade, of course!

The types of knife locks can be quite intricate, but hopefully, after reading this article, you have a clearer understanding. For everyday use, worry less about the lock type on your knife and focus more on whether your knife meets your needs and suits your taste. Most of the mentioned locks are perfectly safe and reliable for everyday use.

Slovakia

Slovakia  Czech Republic

Czech Republic  Austria

Austria  Germany

Germany  Hungary

Hungary  Romania

Romania  Poland

Poland