Knife steel

- What kind of steel is the best for knife?

- Is the knife I would like to buy made from a quality steel, or is it just a mud?

- Will the knife rust?

- Will it get blunt quickly?

- Can I grind it myself at all?

- Do you ask yourself such questions?

If so, this article should help you orient yourself in different knife steels and their key properties. This article will not list the chemical compositions of individual steels, nor the technical terms from metallurgy or mechanical engineering. We want this article to help those who know absolutely nothing about knives and steels. Hopefully, this simplified approach helps you choose the right knife.

Key properties

When choosing a knife steel, you must again consider the purpose for which you want to use the knife.

For food processing? Here you will appreciate the blade stability and stainless steel.

For nature trips? Here you will appreciate a knife made of tough steel, which you will not break when chopping wood for fire. On the other hand, you will want it to be easy to sharpen, because you do not have a professional grinder with you.

For taking with you? Again, you will definitely appreciate the stainless steel, as your sweat can be aggressive and soon you would see rusty dots on the carbon blade, which you will certainly not enjoy.

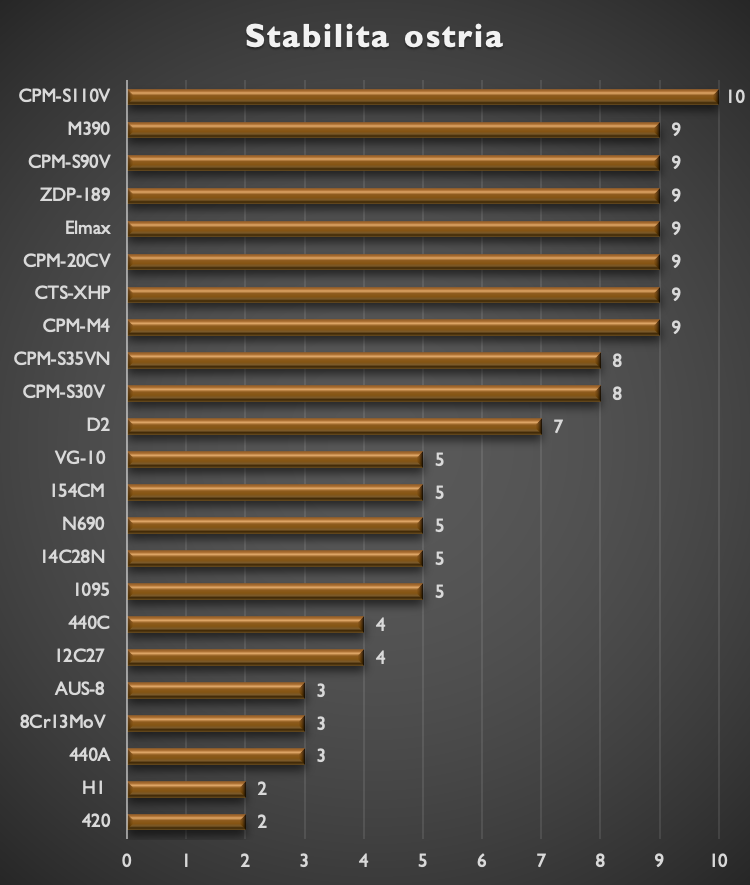

- Blade stability - the ability of the steel to hold the blade during use. Whether you use a kitchen knife for food, you need to cut a twine, carton, or sharpen a branch, no one would be pleased with a blunt knife. Therefore, you will appreciate premium steels that will withstand sharper many times longer than lower grade steels.

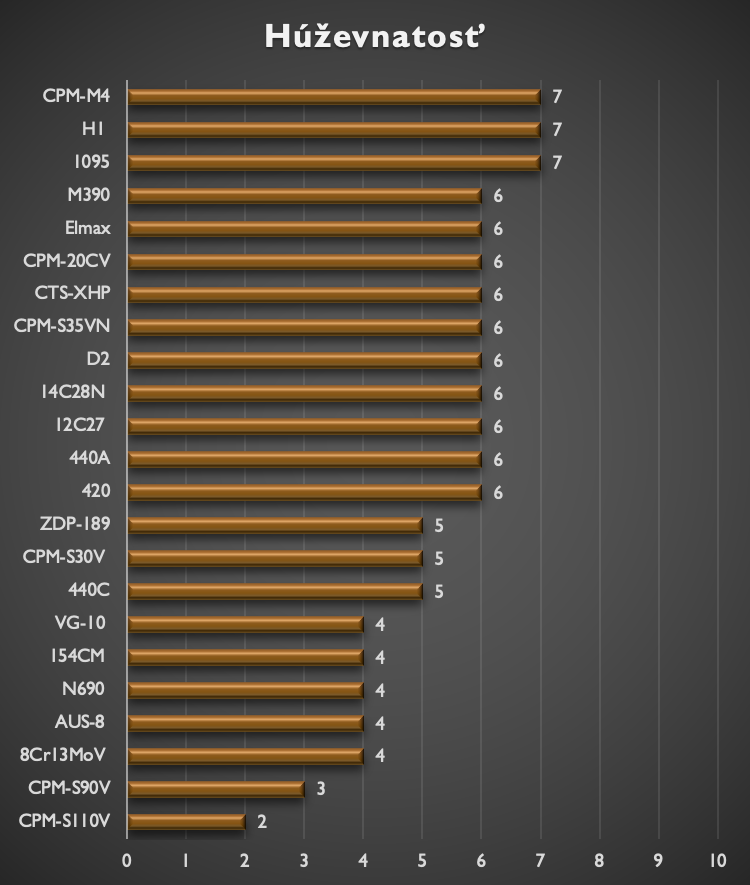

- Toughness of steel - the relative material resistance to breakage, chipping, or cracking under impact or the ability of the steel to withstand even harder treatment. If you need to carry a sturdy knife for building a shelter, chop some wood for fire or other similar activities, you will surely appreciate a strong knife. But, please remember, axes are designed for chopping and crowbars for crowbarring. So if you're going to cut wood for your grandmother, you would better use an axe, it would save you a lot of work.

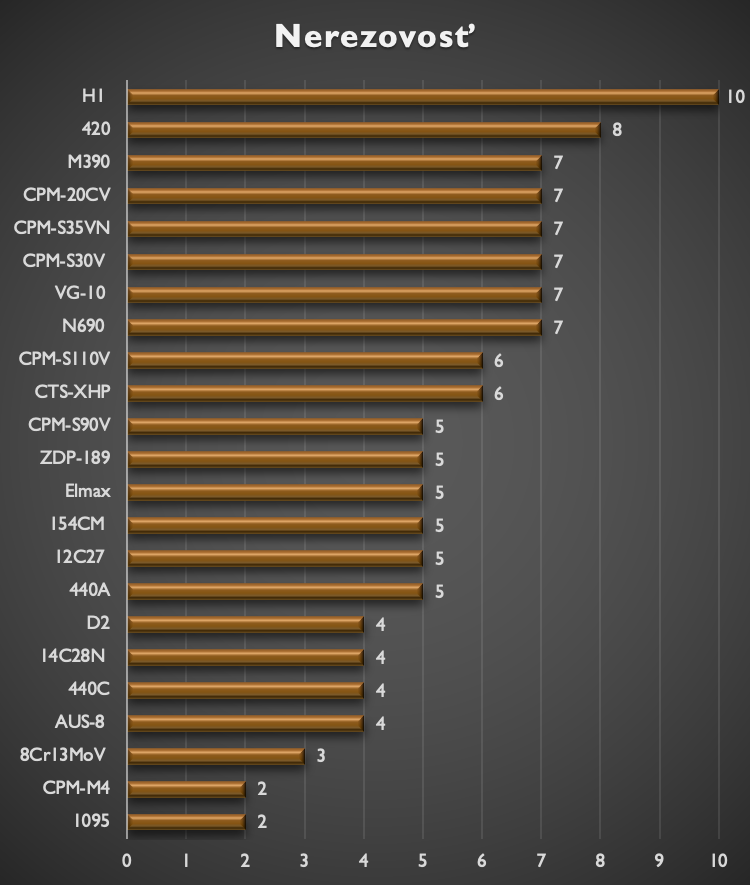

- Stainlessness (corosion resistance) - you will definitely appreciate this feature if you use your knife in a wet environment or for cooking in the kitchen. If you think it takes years for the knife to rust, you are wrong. For example, an ordinary tomato or lemon can cause various damages on a knife with low stainless steel in a short time, from small dots, through a blackened blade, to rusty stains. Also, if you carry a knife in your pocket every day, it may happen that if you do not take care of the knife properly, the sweat will cause the same.

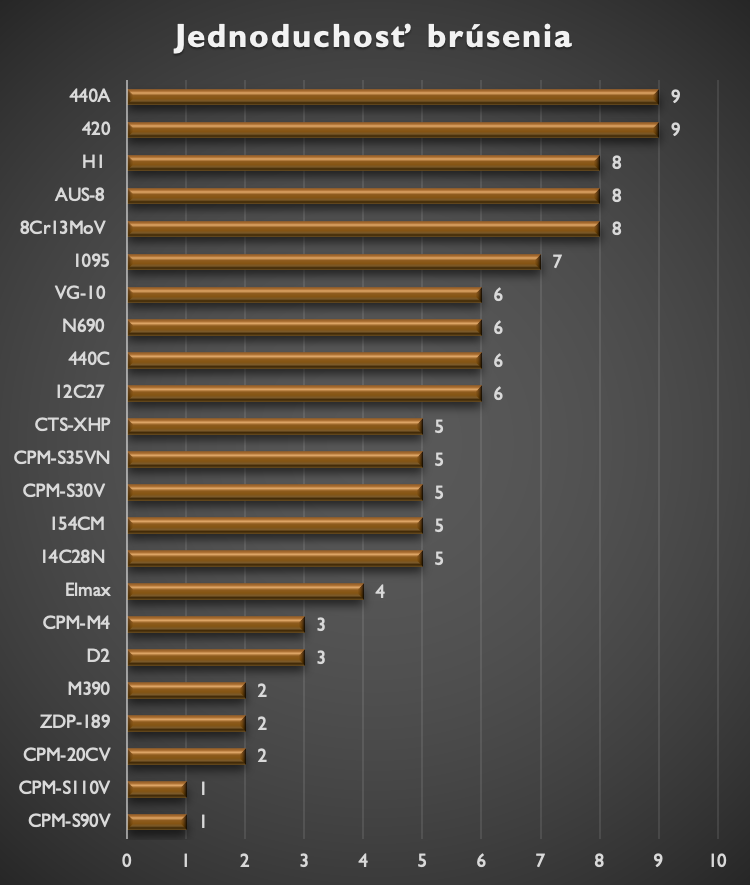

- Easy grinding - this feature is very underestimated and overlooked parameter when choosing a new knife. When you buy a top knife, made of the best steel, you will pay a lot of money for it. You will use it for a while until one day it will not be as sharp as you would like. Do you have anything for sharpening? I guarantee you that the single grinding stone that your grandfather used to use on a scythe will be not enough. So if you are considering premium steels, you will also need a quality grinding system. On the contrary, if you know that you will use the knife for a longer period of time, without the possibility of quality care, you will certainly appreciate that you can sharpen the knife literally on the stone from the river or on an ordinary cup.

Perfect steel would mean a balanced combination of all these properties at the highest level possible. People have been striving for such an ideal steel for centuries, and steel companies are constantly trying to do so. However, the perfect steel does not yet exist. Each feature excels at the expense of the other, so you need to clarify what is your priority and main purpose of your knife. In this comparison, you will see differences between basic type of steels and among the world's best ones.

CPM-S110 M390 CPM-S90V ZDP-189 Elmax CPM-20CV CTS-XHP CPM-M4 CPM-S35VN

CPM-S30V VG-10 D2 154CM H1 N690 14C28N 1095 440C 12C27 AUS-8

8Cr13MoV 440A 420

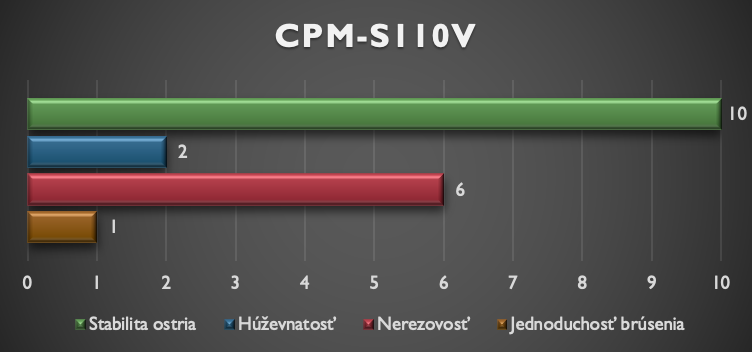

CPM-S110V (Crucible Industries) USA 58-61 HRC

Stainless powdered steel which has incredible blade stability and excellent corrosion resistance. However, due to its low toughness, it is not suitable for larger knives. Furthermore, sharpening is literally hell.

M390 (Bohler Uddelholm) Austria 60-62 HRC

Powdered steel provides an excellent level of blade stability, toughness as well as corrosion resistance. All this makes the M390 one of the most popular premium steels in the world.

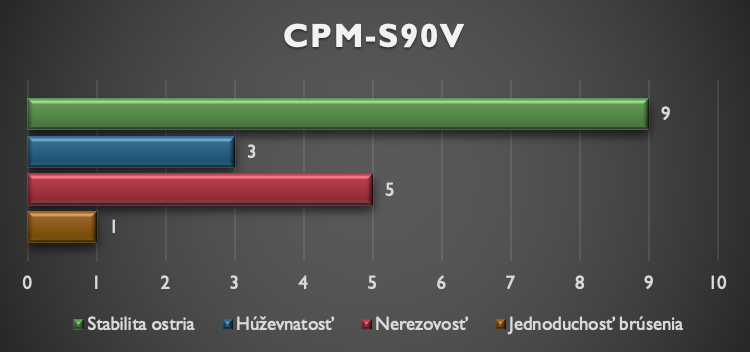

CPM-S90V (Crucible Industries) the USA 58-61 HRC

Powdered steel popular mainly for American producers. It excels in the stability of the blade. However, it is not as tough as the M390 and is much harder to grind.

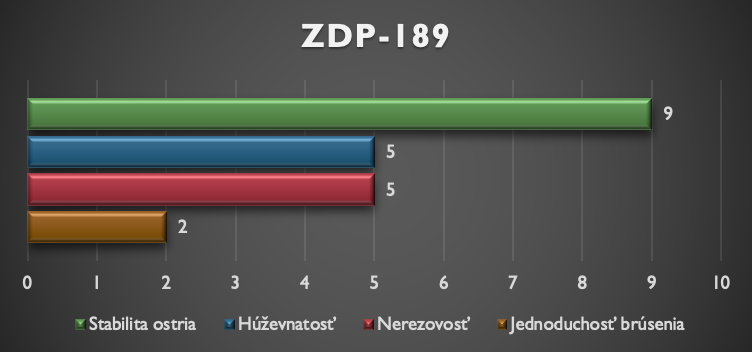

ZDP-189 (Hitachi) Japan 66-67 HRC

One of the hardest steels used in cutlery. It is a great steel, but rarely used mainly because of its high price.

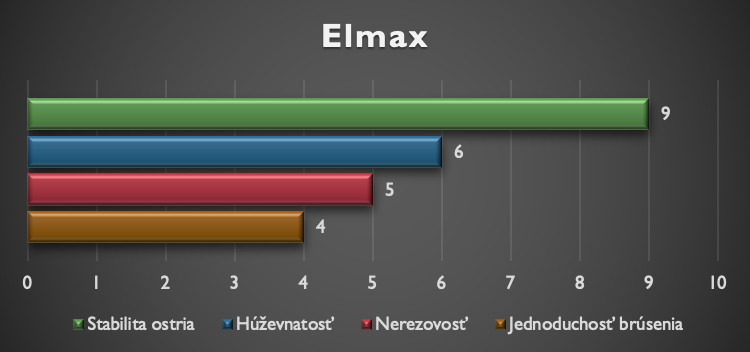

Elmax (Bohler Uddelholm) Austria 60-61 HRC

Quality powdered steel with balanced properties. In comparison to other types of steels in the given category, it can be characterized by better ability to grind.

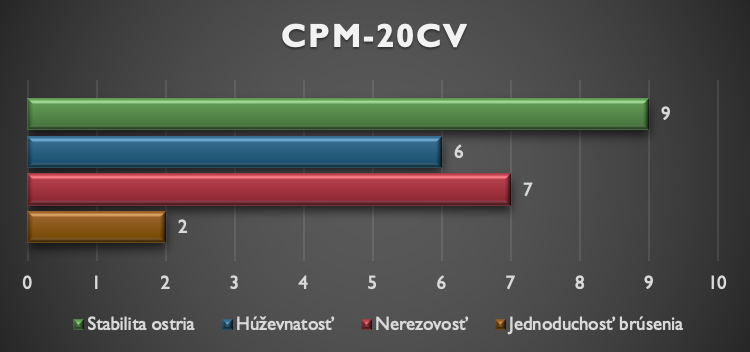

CPM-20CV (Crucible Industries) the USA 59-61 HRC

Excellent blade stability and high corrosion resistance are unusual for the same steel. The CPM-20CV offers both. Great choice for someone looking for great cutting properties with minimal care.

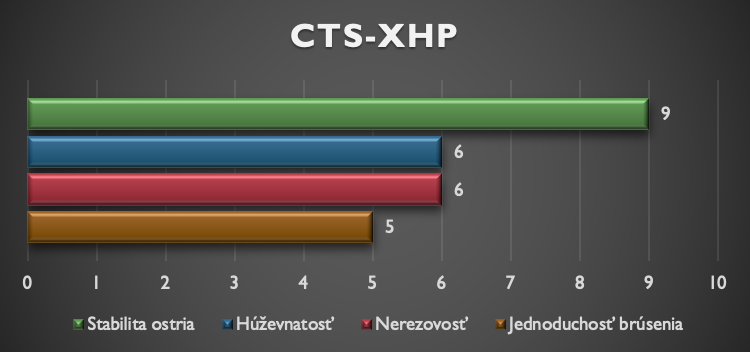

CTS-XHP (Carpenter) the USA cca 64 HRC

This type of steel is described by the producers itself as the equivalent between 440C due to very good corrosion resistance and D2 due to its higher level of toughness and hardness.

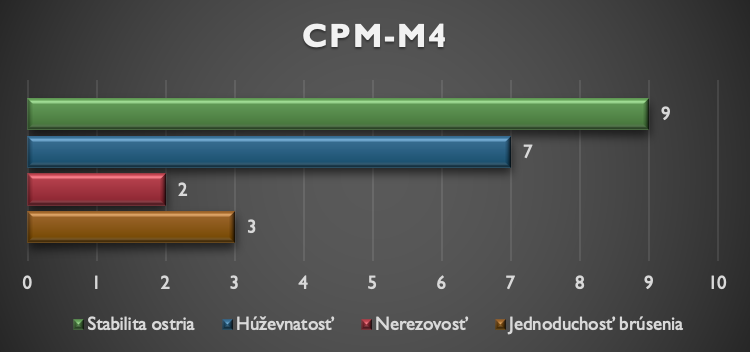

CPM-M4 (Crucible Industries) the USA 60-62 HRC

Powdered steel that is capable of dealing with almost any task. It excels in blade stability and great toughness. However, on the other hand, it requires extreme care to prevent corrosion.

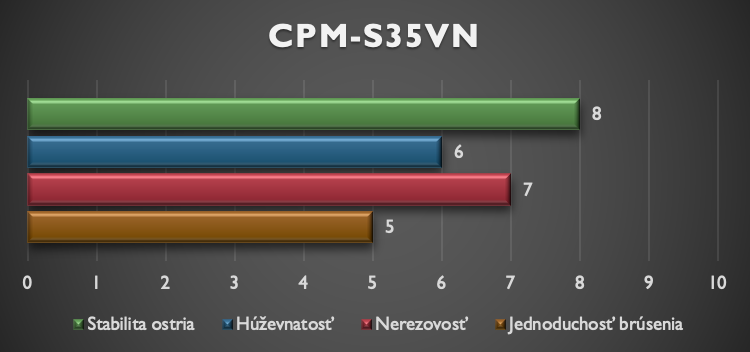

CPM-S35VN (Crucible Industries) the USA 60-61 HRC

Powdered steel, which is an improvement of S30V type of steel. In comparison, this type of steel has higher toughness and it is polishable easily.

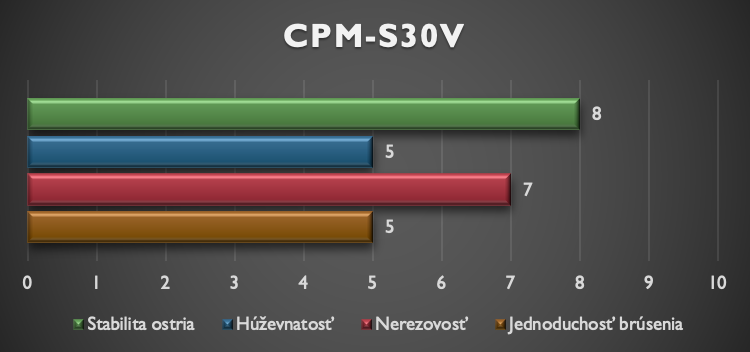

CPM-S30V (Crucible Industries) the USA 58-61 HRC

Powdered steel designed for the production of knives. This steel has excellent corrosion resistance ability and its blade stability is ideal for everyday use as well as outdoor activities.

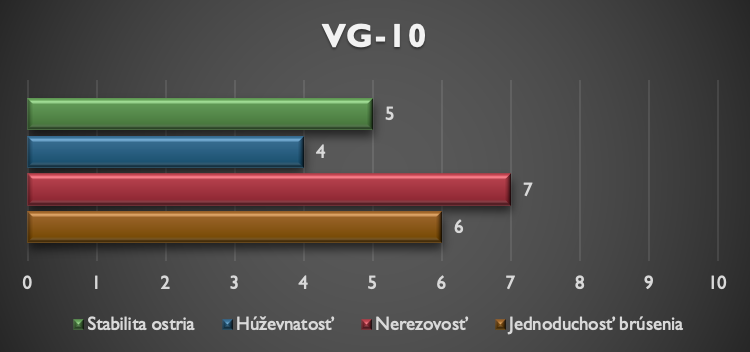

VG-10 (Takefu) Japan 59-61 HRC

Traditional Japanese steel, also known as the "gold standard". Choosing a knife with this type of steel is always a good choice. Furthemore, during recent years, it has become really affordable.

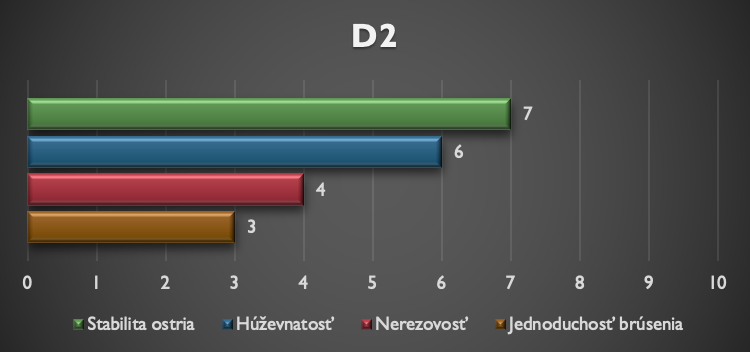

D2 59-61 HRC

Steel developed for cutting other types of steels. D2 offers fantastic toughness and blade retention for harder treatment. However, it is semi-stainless steel, so proper care is required.

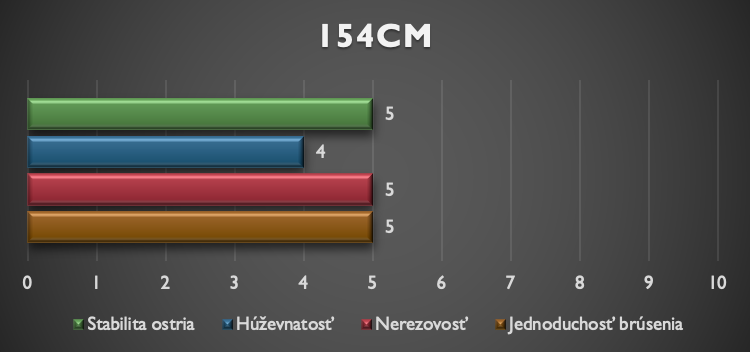

154CM (Crucible Industries) the USA 58-61 HRC

One of the higher quality type of steel used for the production for cutlery. It can be described as a modified 440C steel and has an almost ideal balance of all four key described properties.

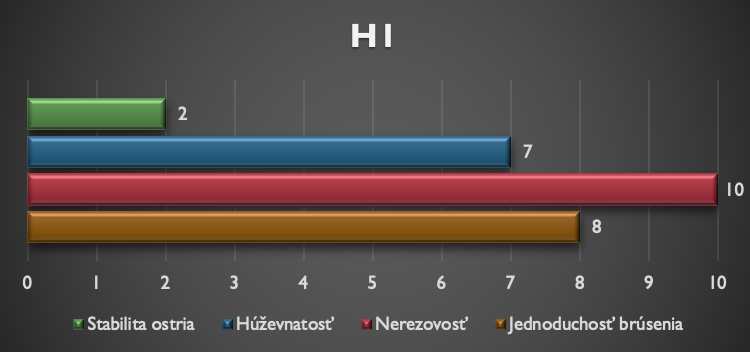

H1 (Myodo Metal) Japan 58-65 HRC

This type of steel is definitely steel with the best corrosion resistance. You can leave a knife in the water and cut whatever you want. No other steel will last that long in this regard. Furthermore, it excels in other parameters except the blade stability which is weaker in comparison to other types of steel.

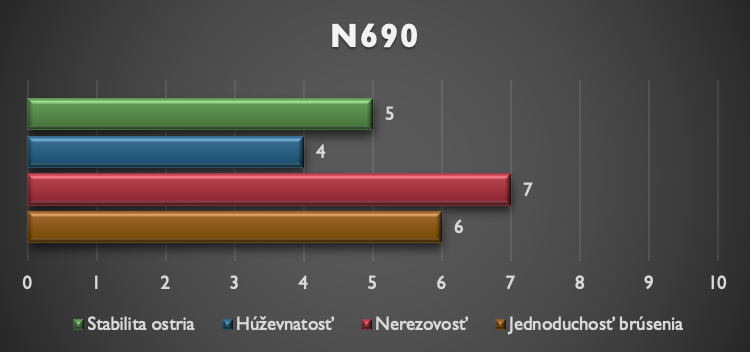

N690 (Bohler Uddelholm) Austria 59-59 HRC

Very popular type of steel in almost all European cutlery companies. It is equivalent to 440C steel with better corrosion resistance.

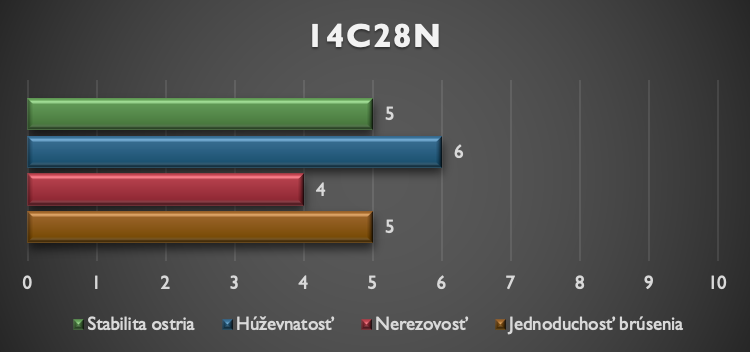

14C28N (Sandvik) Sweden 58-62 HRC

Improved type of 12C27 steel with higher corrosion resistance. Definitely one of the best type of steels on the market in regard its price.

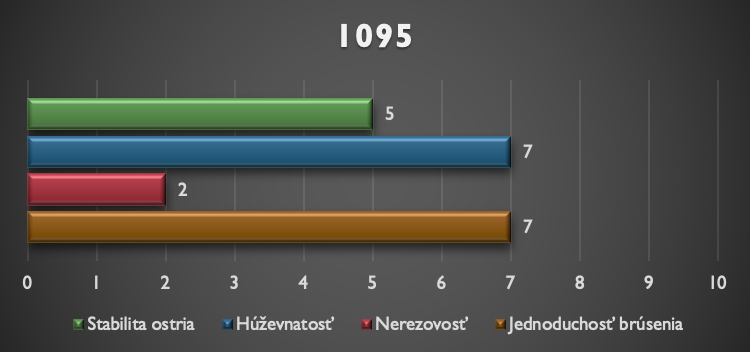

1095 58-66 HRC

The most used carbon steel. It grinds well and you can easily reach a really sharp blade. It is very tough, holds the blade well and is very affordable. However, this type of steel has also weakness: the low corrosion resistance, which is the reason why many producers cover it with a protective layer.

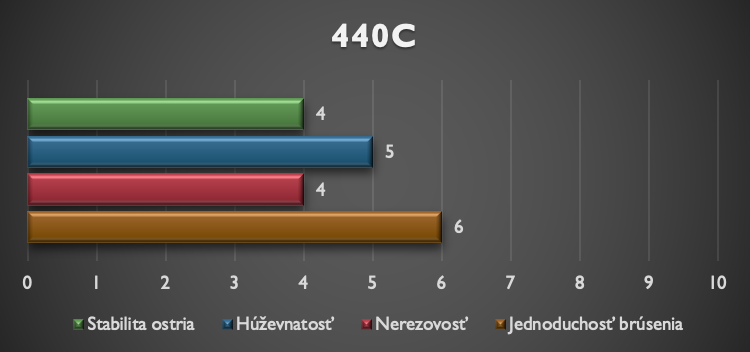

440C 58-60 HRC

Probably the most used type of steel in the world. It is popular mainly for a good balance of all its features and excellent value for money.

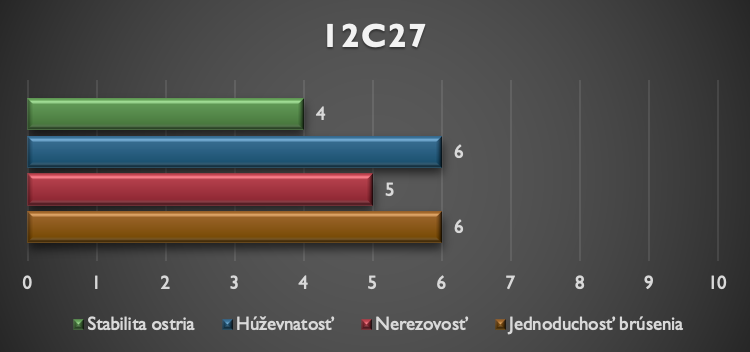

12C27 (Sandvik) Sweden 57-59 HRC

Great type of steel appropriate for everyday use. It is widely used by Morakniv and Opinel. Despite the low prices of knives, this type of steel has a great properties. The price-quality ratio is almost unbeatable.

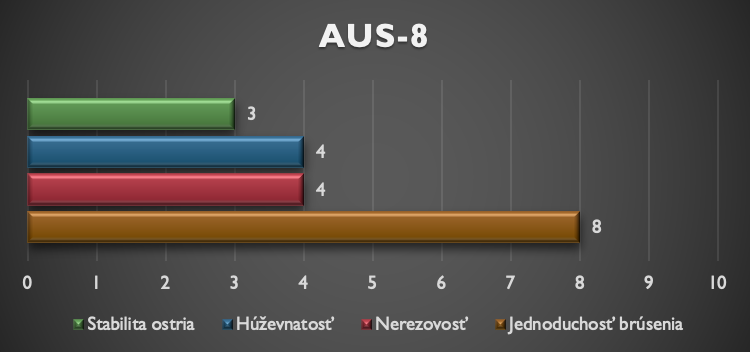

AUS-8 (Aichi Steel) Japan 57-59 HRC

This type of steel can be compared to 12C27 or 440C. The blade holds a little worse, but on the other hand it grinds very easily.

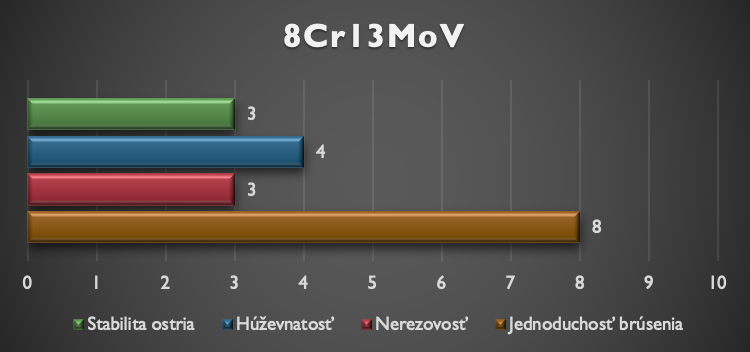

8Cr13MoV (Ahonest) China 57-59 HRC

Chinese version of AUS-8. It holds the blade better and it is cheaper. It is used, for example, by Spyderco or Kershaw for the production of knives.

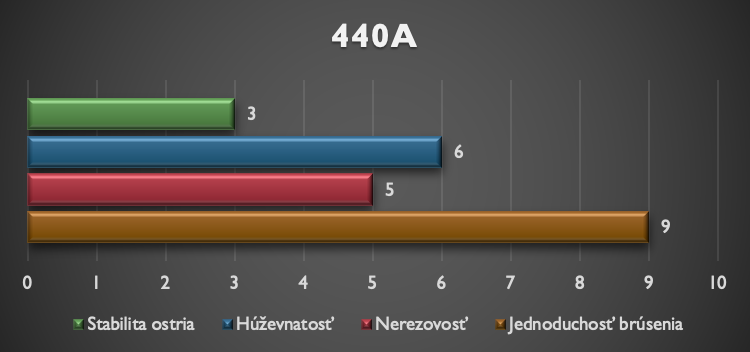

440A 56-57 HRC

Although this type of steel is only used for the production of knives of a lower price category, in addition to the stability of the blade, it has also other properties at a very good level.

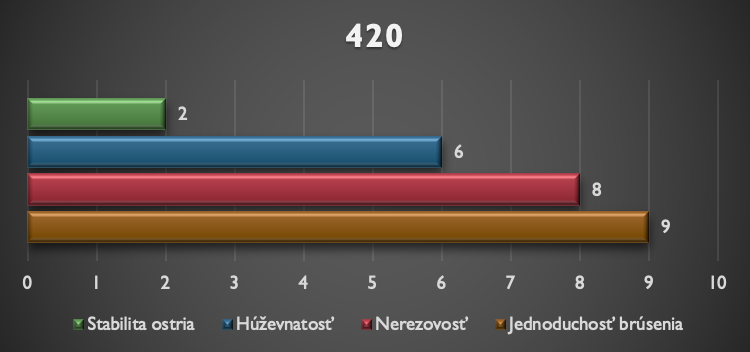

420 54-56 HRC

The most common and cheapest type of steel for the production of knives. Majority of cheap and no-brand knives are made of this type of steel. But if you don't mind sharpening a knife almost every day, you will definitely appreciate the other properties of this type of steel.

Ranking of key properties

We recommend from the category All kitchen knives

Cold Steel Slice Kitchen Knife 22.9 cm

Böker Plus Set of Kitchen Knives 03bo024 24 pcs

Mula Damascus Steinless VG10 Sandw.-15dam.m 15cm

XINZUO B37 7 inch santoku knife olive wood 73 layers Damascus steel with 14Cr14V3

Cold Steel Commercial Series Big Country Skinner knife 15.2 cm 20VBSKZ

Spyderco Counter Puppy Purple knife 8.8cm k20pPR

Böker core butcher's knife 20.7 cm 130760 brown

OTTARIO OLD HICKORY 417 Fillet Knife 6.25 "440C Blade, Hardwood Handles, Leather Sheath On1275

Slovakia

Slovakia  Czech Republic

Czech Republic  Austria

Austria  Germany

Germany  Hungary

Hungary  Romania

Romania  Poland

Poland